COPMA

COPMA 60

COPMA 60

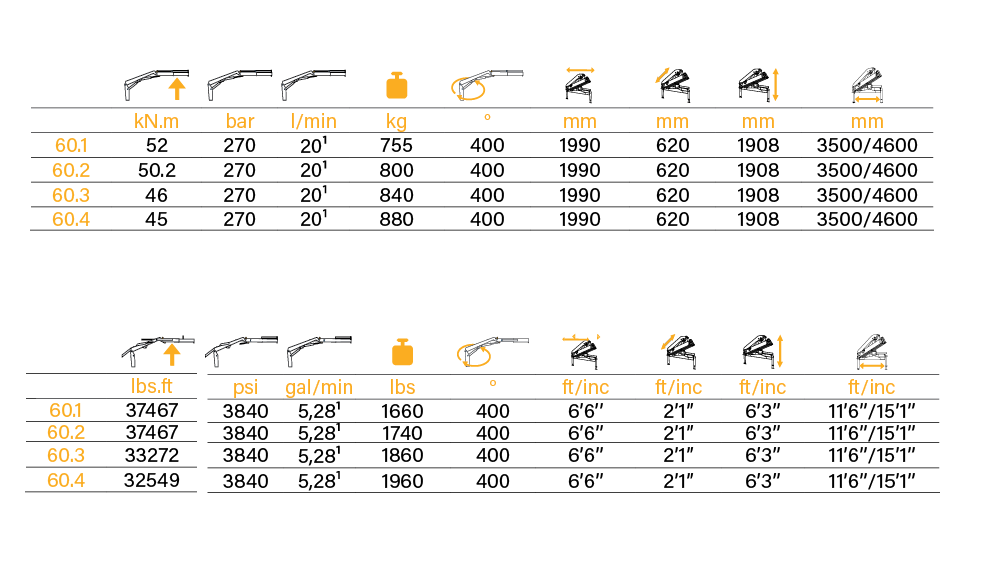

LOADER KNUCKLE BOOM CRANE

- ESSENTIAL model, over 6 Ton/Mt.

- Essential in design, powerful in performance

- Robust arm system

- Simple and reliable

- Excellent operational safety

60 is innovative in engineering for top precision, efficiency, speed, and performance. An essential piece of lifting technology.

COPMA® Remote Connectivity 4.0 to the crane. Two-way communication by GPRS for real-time diagnosis and remote real-time parameter setting and/or adjustment.

Constant Control Link System. The cranes equipped with connecting rods on the articulations, with a constant lifting moment over the entire working arc, allow to 100% optimize the crane’s capacity in positions close to the maximum vertical.

Crane Monitoring system 1.0. Crane stability control system TES1-TES2, with safety control and overload control for medium-small cranes. Controls the crane in 4 work areas, and each zone can have custom lifting settings depending on the vehicle stability.

Manual Lifting Stabilizers 1.0. Manual lifting of the crane legs.

The manual lifting of the legs helps the operator adjust its extension manually without additional assistance from electronics or hydraulic controls.

Radio Remote Control 2.0. Radio remote control with the electro-hydraulic actuator connected directly to the standard control valve. The remote control allows operating the crane while continually monitoring the areas of operation.

Radio Remote Control 3.0. Radio remote control with the electro-hydraulic actuator connected directly to the proportional control valve. The remote control allows operating the crane while continually monitoring the areas of operation.

Rotation Rack Pinion. The rotation system with rack and pinion is the best optimal solution for the most performative lifting capacity. It reduces the weights and the crane dimension for the most compact configuration.

Transport Alert Device. Sensors on the basement controls the correct closing of the beams, and a column switch sensor indicates the crane folded position, no more than 4 mt in height. The operator is warned with light and sound signals in the truck cabin.

Truck Electronic Stability 1.0. Active stability control for performance optimization according to the type of stabilization to guarantee maximum safety in all working conditions. Mandatory in the CE market, it helps a better vehicle-crane configuration.